Vulcanizing presses and autoclaves, such as Uzer Makina and Italmatic.

Rubber and elastomers.

Max part size: 1000mm x 1000mm. Tolerances: ±0.1mm.

Quality Management System: ISO 9001:2015 certified, ensuring high-quality vulcanized products.

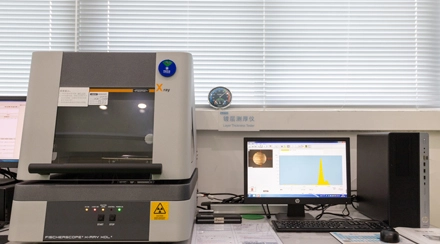

Inspection Equipment: Hardness testers, tensile testers, and CMM.

Quality Assurance Process: Material verification, in-process monitoring, and final inspection using hardness and tensile testers to ensure material properties and quality.

Vulcanization is a chemical process that transforms raw rubber into a more durable, elastic, and heat-resistant material by introducing sulfur or other curatives. This process is essential for enhancing the physical properties of rubber, making it suitable for a wide range of industrial and consumer applications. Here is a brief overview of the meaning and importance of vulcanization:

Definition: Vulcanization is the process of heating raw rubber with sulfur, accelerators, and other additives to create cross-links between the polymer chains. This chemical reaction changes the rubber’s molecular structure, resulting in improved mechanical properties.

Process: The vulcanization process typically involves mixing raw rubber with sulfur and other chemicals, followed by heating the mixture under controlled conditions. The heat and chemicals cause the sulfur atoms to form cross-links between the long rubber molecules, creating a three-dimensional network.

Enhanced Properties: The primary benefits of vulcanization include increased elasticity, tensile strength, and resistance to abrasion, chemicals, and temperature changes. These enhanced properties make vulcanized rubber ideal for various applications, from automotive tires and industrial belts to medical devices and consumer goods.

Applications: Vulcanized rubber is used in numerous industries due to its improved durability and performance. Common applications include tires, hoses, seals, gaskets, footwear, and conveyor belts. The process also allows for the production of specialized rubber products with specific properties tailored to particular uses.

Historical Significance: The discovery of vulcanization by Charles Goodyear in the 19th century revolutionized the rubber industry, enabling the mass production of high-quality rubber products. This breakthrough has had a lasting impact on modern manufacturing and continues to be a cornerstone of rubber processing.

By understanding the meaning and importance of vulcanization, manufacturers can produce superior rubber products that meet the demanding requirements of various applications, ensuring reliability and longevity.

1. Tires

Vulcanized rubber is essential in tire manufacturing, providing the necessary durability and flexibility for vehicle performance.

2. Seals and Gaskets

These products are used to prevent leaks in various applications, including automotive engines and industrial machinery, ensuring a tight fit and resistance to fluids.

3. Hoses

Vulcanized rubber hoses are used in automotive, industrial, and agricultural applications, offering flexibility and resistance to heat, chemicals, and abrasion.

4. Belts

Vulcanized rubber belts, such as conveyor belts and timing belts, are utilized in manufacturing and automotive applications for power transmission and material handling.

5. Footwear

Soles and other components of shoes are often made from vulcanized rubber, providing comfort, durability, and slip resistance.

6. Rubber Mats

These mats are used in various settings, including gyms, workplaces, and homes, providing cushioning, traction, and protection against slips and falls.

7. Automotive Components

Vulcanized rubber is used in various automotive parts, such as bushings, mounts, and vibration isolators, to reduce noise and absorb shocks.

8. Electrical Insulation

Vulcanized rubber is employed in electrical insulation products, such as cables and connectors, due to its excellent dielectric properties.