What Is Lost Plastic Casting?

Lost plastic casting, also known as full mold casting or evaporative pattern casting, is an innovative casting method that uses wax or foam patterns, which resemble the shape and dimensions of the final casting. These patterns are assembled into clusters, coated with refractory material, dried, and then buried in dry quartz sand using vibration molding. Under vacuum or negative pressure, molten metal is poured into the mold. As the metal enters, the foam pattern vaporizes, allowing the liquid metal to fill the cavity. Upon solidification and cooling, the final casting is formed. This process allows for high precision and excellent surface finish.

Advantages of Lost Plastic Casting

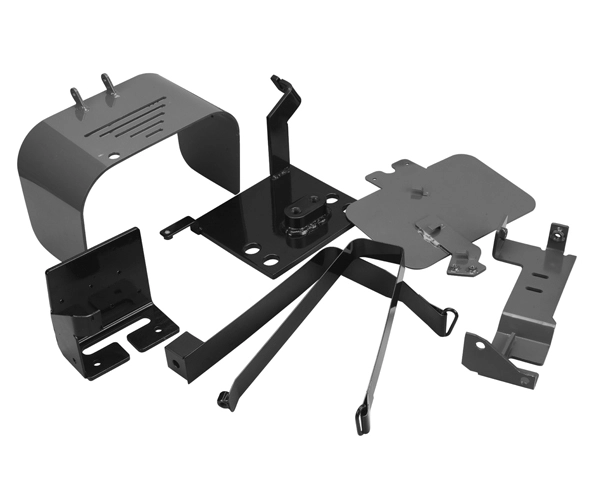

High Dimensional Accuracy

Lost plastic casting is a near-net-shape precision forming process. It eliminates the need for mold extraction, parting lines, and sand cores. As a result, the castings have no flash, burrs, or draft angles, and dimensional deviations due to core assembly are significantly reduced. The surface roughness of castings can reach Ra 3.2–12.5 μm, and dimensional accuracy can reach CT7–CT9. Machining allowances are minimal, typically only 1.5–2 mm, which reduces machining costs and time by 40%–50% compared to traditional sand casting.

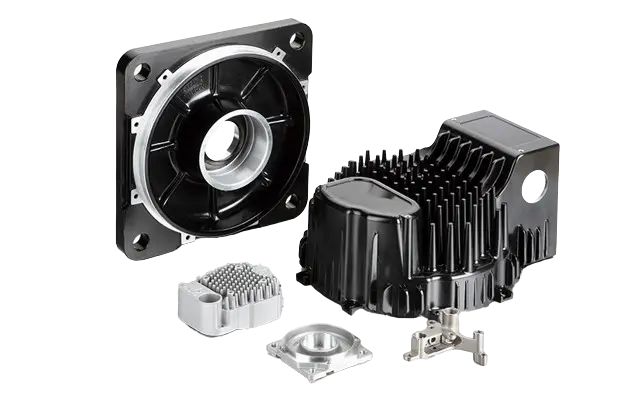

Design Flexibility

This method provides exceptional design freedom, allowing for the casting of highly complex geometries by assembling foam pattern segments, making it ideal for intricate components.

No Traditional Sand Cores

Lost plastic casting eliminates the need for sand cores, thus avoiding issues such as wall thickness inconsistencies caused by inaccurate core dimensions or misplacement during core setting.

Clean Production

As no chemical binders are used in the molding sand, and foam materials are relatively environmentally benign when burned at low temperatures, this process is environmentally friendly. The sand can be reused, with a recovery rate of over 95%.

Lower Investment and Production Costs

The casting blanks produced are lighter with minimal machining allowance, resulting in material savings and reduced overall manufacturing cost.

Common Lost Plastic Casting Technologies

Pressure Lost Plastic Casting

This method integrates lost plastic casting with pressure solidification technology. During casting, the metal is poured into a mold within a sealed pressure chamber. After the foam pattern vaporizes, the chamber is sealed, and pressurized gas is introduced. This controlled pressure environment promotes directional solidification, reduces casting defects such as shrinkage cavities and porosity, improves the density, and enhances the mechanical properties of the casting.

Vacuum Low-Pressure Lost Plastic Casting

This technique combines negative pressure lost plastic casting with low-pressure counter-gravity casting. It utilizes controlled air pressure to assist metal flow into the mold cavity, significantly improving mold filling capacity. Compared to die casting, it requires less equipment investment and lower cost. The castings are heat-treatable, with higher precision and surface finish than sand casting. The casting system is simple and efficient, with high yield and dense microstructure. This method also supports a wide range of non-ferrous alloys and operates at relatively low pouring temperatures.

Vibrational Lost Plastic Casting

In this technique, a certain frequency and amplitude of vibration is applied during the casting process. The vibration facilitates the movement between the solid and liquid phases of the metal, fragmenting dendrites and increasing nucleation points. This results in refined grain structure, improved feeding, and enhanced mechanical properties. It makes use of existing compaction vibration tables and vibratory motors to generate mechanical vibrations, making it a low-cost, easy-to-operate, and environmentally friendly solution.

Lost plastic casting, as a near-net-shape forming technique, has experienced rapid development in recent years. The deployment of automated and mechanized production lines, along with their significant economic and social benefits, has demonstrated the robust vitality of this casting method. With its high precision, design versatility, cost-effectiveness, and environmentally friendly attributes, lost plastic casting continues to gain prominence in modern foundry technologies.

English

English