Dimensional Precision Equipment

Industry-leading Hexagon 3D Coordinate Measuring Machines and Projectors deliver micron-level accuracy for custom parts, ensuring full compliance with design specs and zero dimensional deviations.

Key Equipment: Hexagon CMM, Hexagon Projector etc.

Testing Scope: Dimensional tolerance, geometric shape, contour accuracy checks

Customer Benefit: Precise fit and function for automotive & all industrial custom parts

Material Mechanical Property Equipment

Hardness Testers and Universal Tensile Testing Machines verify core material properties, validating strength and durability to prevent premature part failure.

Key Equipment: Vickers/Rockwell/Brinell Hardness Tester, Universal Tensile Testing Machine etc.

Testing Scope: Hardness, tensile strength, yield strength, elongation at break

Customer Benefit: Long-term reliability under operational stress

Environmental & Surface Performance Equipment

Chambers and testers simulate harsh real-world conditions to test corrosion resistance, temperature stability, and surface quality, ensuring part performance in extreme environments.

Key Equipment: High-Low Temperature & Humidity Chamber, Salt Spray Tester, Surface Profiler etc.

Testing Scope: Corrosion resistance, temperature cycling, surface roughness analysis

Customer Benefit: Proven longevity for automotive & outdoor industrial applications

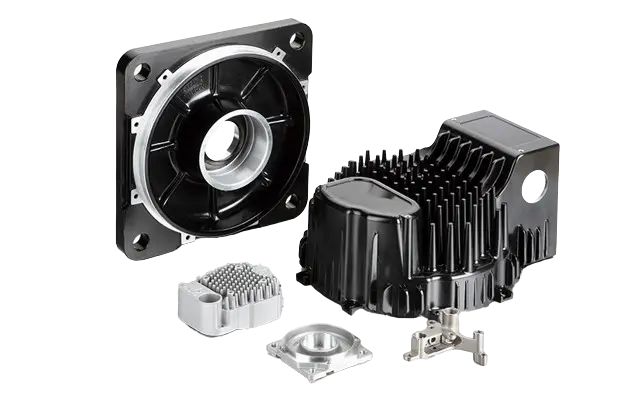

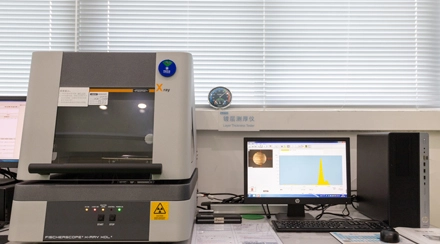

Advanced Composition & Performance Validation Equipment

A comprehensive testing suite delivers in-depth validation of material purity, coating integrity, and rotational stability, ensuring parts meet the strictest industry standards.

Key Equipment: German Fisher X-ray Thickness Gauge, Schenker Dynamic Balancing Tester, Spectrometer Grinder, Metal Analyzer etc.

Testing Scope: Material composition, coating thickness, dynamic balance verification

Customer Benefit: Consistent quality for high-precision custom components

English

English