CNC automatic lathes such as Citizen Cincom L32 and Star SR-20RIV, equipped with bar feeders and live tooling.

Metals (brass, stainless steel, aluminum), plastics, and composites.

Max workpiece diameter: 32mm. Tolerances: ±0.005mm.

Quality Management System: ISO 9001:2015 certified, focusing on precision and reliability.

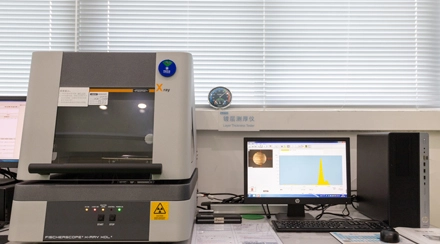

Inspection Equipment: Optical comparators, CMM, and digital calipers.

Quality Assurance Process: Rigorous incoming material checks, real-time process monitoring, and final inspection using CMM and optical comparators to ensure dimensional accuracy.

Discover the unparalleled efficiency and precision of our state-of-the-art automatic lathe machining. Designed for high-volume production, this machine ensures consistent quality and reduces cycle times, making it the perfect addition to any modern manufacturing facility. Whether you’re producing intricate components or high-precision parts, our automatic lathe delivers exceptional performance and reliability. Explore the features and benefits that set our automatic lathe apart and see how it can transform your production process.

High Production Efficiency: Automatic lathe machining can operate continuously, reducing the need for manual intervention and increasing production speed.

Versatility: Automatic lathe machining can process a variety of materials and complex shapes, adapting to different production needs.

Increased Safety: Automatic lathe machining reduces the risk of worker exposure to hazardous equipment, enhancing workplace safety.

Programmability: Many automatic lathes can be programmed for quick setup and adjustment, making it easy to switch between different production tasks.

Long Operating Hours: Automatic lathe machining can run during the night or in unattended conditions, improving production continuity.

The main difference between an automatic lathe and a semi-automatic lathe lies in their level of automation during the machining process. An automatic lathe performs operations like turning, drilling, and cutting with minimal human intervention. It is fully programmable and ideal for high-volume automatic lathe machining, offering faster cycle times and greater consistency. In contrast, a semi-automatic lathe requires an operator to manually load or adjust parts between machining steps. While it provides more control and flexibility, it is slower and less efficient for mass production compared to automatic systems.

Automotive Industry: Produces precision parts like shafts, bolts, and bushings for engines, transmissions, and suspension systems, ensuring tight tolerances and high output.

Aerospace: Manufactures complex components such as turbine pins, fittings, and fasteners, meeting strict dimensional and material requirements for safety and performance.

Medical Devices: Creates intricate parts like surgical screws, implants, and instrument components, requiring high precision and biocompatible materials.

Electronics: Fabricates small, detailed parts like connectors, terminals, and housings for devices, ensuring consistent quality for high-volume production.

Industrial Machinery: Produces durable components like gears, spindles, and couplings for heavy equipment, designed for reliability under demanding conditions.

Consumer Goods: Manufactures precision parts for appliances, watches, and tools, such as screws, knobs, and fittings, with excellent surface finishes.

Plumbing and Hydraulics: Creates fittings, valves, and nozzles with precise threading and sealing surfaces for leak-proof performance in fluid systems.