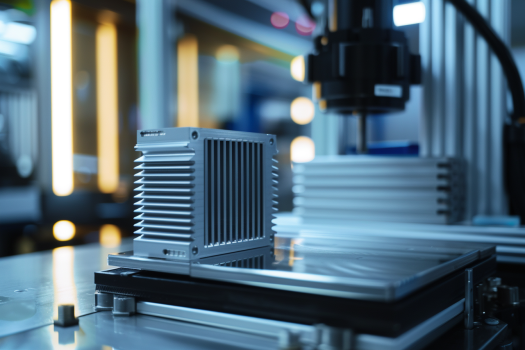

The maximum diameter of CNC processed parts is up to 600mm.

The min diameter of precision cnc machining parts is 1.0 mm

The max length of cnc precision parts is up to 1000mm

Up to 3000mm (Diameter < 55mm)

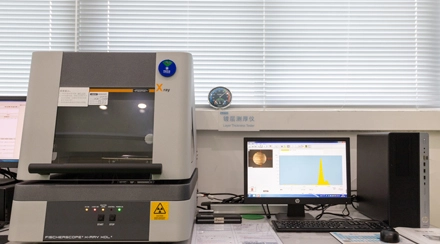

BulkTEK provides comprehensive testing and inspection services to ensure the highest quality standards for your products. Our processes are strictly in accordance with ISO 9001 standards, ensuring consistent and reliable results. BulkTEK Laboratory boasts municipal-level standard testing and inspection capabilities, equipped with state-of-the-art professional testing and inspection equipment. This allows us to handle various parts inspection requirements internally, eliminating the need for external inspections and thereby reducing delivery times.

To maintain the accuracy and reliability of our measurements, BulkTEK regularly submits its testing and inspection equipment to professional calibration institutions for annual calibration. This commitment to precision ensures that you receive accurate and dependable data for your products. Trust BulkTEK for all your testing and inspection needs, backed by our rigorous quality management system and advanced capabilities.

PPAP Level 3 document

EN10204 - 3.1

Initial Samples Report

Pre‐Shipment Inspection Report

Third Party Test Report(RoHS & Reach)

| Finishing | Description |

| Electroplated coating systems (zinc, Zinc-nickel, tin, etc.) | Applies a metallic layer via electroplating to enhance corrosion resistance and appearance. |

| Zinc flake coatings (Geomet 321/500/720 etc.) | Provides high-performance corrosion protection without electroplating, ideal for automotive use. |

| Hot dip galvanized (H.D.G.) | Immerses parts in molten zinc to form a thick, durable coating for excellent outdoor corrosion resistance. |

| Mechanical galvanizing/ Sherardizing | Forms a zinc layer through mechanical or diffusion processes, suitable for small or threaded parts. |

| Chemical nickel plating | Deposits a uniform nickel layer through a chemical reaction, offering excellent wear and corrosion resistance. |

| Anodizing / KTL | Creates a corrosion-resistant oxide layer or applies a uniform electrophoretic coating, often for aluminum parts. |

| Powder coatings | Uses electrostatic application of powder followed by curing to create a strong, colorful protective finish. |

| Pickling and passivation | Removes surface contaminants and enhances stainless steel’s corrosion resistance through chemical treatment. |

| Phorspating | Adds a phosphate layer to improve paint adhesion and provide basic corrosion protection. |

| Black oxide | Forms a dark oxide film on metal surfaces to reduce glare and provide mild corrosion resistance. |

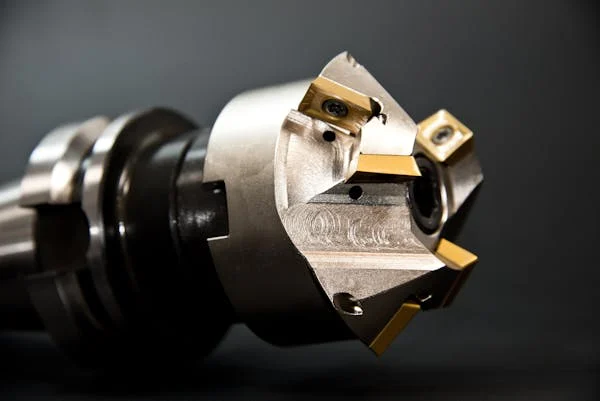

CNC (Computer Numerical Control) machining is a manufacturing process that utilizes computerized controls to operate and manipulate machine tools such as lathes, mills, routers, and grinders. The process begins with a digital design, typically created using CAD (Computer-Aided Design) software. This design is then converted into a CNC program, often using CAM (Computer-Aided Manufacturing) software, which generates a series of precise instructions (G-code) that guide the machine’s movements.

CNC machining offers high precision, repeatability, and efficiency, making it ideal for producing complex parts with tight tolerances. The process can handle a wide range of materials, including metals, plastics, wood, and composites. It is widely used in various industries, such as aerospace, automotive, medical, and electronics, for both prototyping and full-scale production.

One of the key advantages of CNC machining is its ability to produce consistent and high-quality parts with minimal human intervention, reducing the likelihood of errors and increasing production speed. Additionally, CNC machines can operate continuously, 24/7, further enhancing productivity. The technology also allows for quick adjustments and modifications, making it highly adaptable to changing design requirements and production needs.

High Precision and Accuracy: BulkTEK utilizes advanced CNC technology to produce parts with exceptional precision, ensuring they meet strict tolerances and specifications.

Rapid Prototyping: The company can quickly produce prototypes, allowing for faster iterations and improvements during the design phase.

Versatile Material Options: BulkTEK offers machining services for a wide range of materials, including metals, plastics, and composites, catering to diverse project requirements.

Custom Solutions: They provide tailored machining services to meet specific client needs, ensuring that every part is designed and produced according to individual specifications.

Short Lead Times: The efficient workflow and modern machinery enable BulkTEK to offer shorter lead times, helping clients meet tight deadlines.

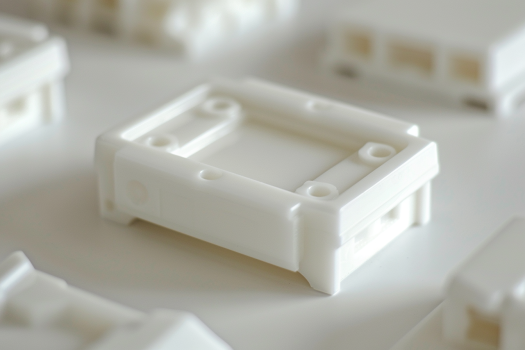

CNC Machining: CNC (Computer Numerical Control) machining involves removing material from a solid block (usually metal, plastic, or wood) using cutting tools like mills, lathes, or drills. The material is gradually shaped to the desired specifications via precise, computer-controlled movements. Offers very high precision and smooth surface finishes. CNC machines can achieve tolerances as tight as 0.001 mm, making them ideal for producing parts that require exact dimensions and a high-quality finish.

3D Printing: 3D printing, or additive manufacturing, builds objects layer by layer based on a digital model. It adds material (usually plastic, resin, metal powder, or even concrete) in precise layers to create the final part, unlike CNC, which removes material. While some 3D printing technologies (like SLA or SLS) can produce detailed parts, the surface finish typically isn’t as smooth as CNC-machined parts. Additionally, precision in 3D printing can be lower, especially with more affordable FDM (Fused Deposition Modeling) printers.

8.8, 10.9, 12.9

AISI 1215、AISI 12L14、AISI 1144

SUS303, SUS304, SUS316/316L, SUS316Ti

AW6082,AW6061,AW7075,AW2024,AW5754

Zamak 3, Zamak 5

PP, PA6, PA66, PVC, ABS, POM,PTEF, HDPE

BulkTEK supplied special machining parts to medical equipment manufacturers

BulkTEK has been cooperating with GROSS, a top rail industry distributor, since 2017. Today, GROSS supplied products to China Railways, German Railways and Polish Railways.

The robot industry has abundant customization needs and requires high product accuracy. Our products are highly recognized by top international robot manufacturing companies.

BulkTEK provides related products to wind power and photovoltaic companies.