Hydraulic compression molding presses, including Wabash MPI Genesis and French Oil PH Series.

Plastics, rubber, and composites.

Max mold size: 1000mm x 1000mm. Tolerances: ±0.1mm.

Quality Management System: ISO 9001:2015 certified, ensuring high-quality molded parts.

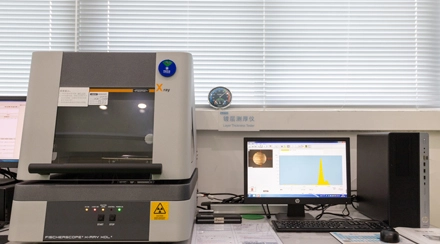

Inspection Equipment: CMM, digital calipers, and tensile testers.

Quality Assurance Process: Material verification, mold inspection, and final part inspection using CMM and tensile testers to ensure dimensional accuracy and material strength.

| Feature | Transfer Molding | Compression Molding |

|---|---|---|

| Process | Material is preheated, then forced into a closed mold cavity through a runner system | Material is placed directly in an open mold cavity, then compressed |

| Tooling Complexity | More complex tooling with additional runner and pot system | Simpler tooling with no runners |

| Part Complexity | Suitable for complex shapes and inserts | Best for simpler, flatter parts |

| Cycle Time | Typically faster due to preheating and flow | Generally slower because heating occurs in the mold |

| Material Waste | More waste due to sprues and runners | Less waste, since all material is used in the part |

| Cost | Higher tooling cost | Lower tooling cost |

| Consistency | Better dimensional accuracy and consistency | May have more variation in thick or uneven parts |

| Use Cases | Electronic components, encapsulation, precision parts | Gaskets, seals, large simple rubber parts |