Foam pattern making machines and vacuum casting systems, including FOAM-iT! 10 and V-Process 3000.

Metals (aluminum, steel, bronze).

Max casting size: 800mm x 800mm x 400mm. Tolerances: ±0.3mm.

Quality Management System: ISO 9001:2015 certified, ensuring high-quality lost pattern castings.

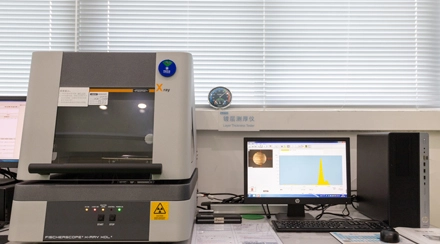

Inspection Equipment: CMM, X-ray inspection, and spectrometers.

Quality Assurance Process: Material verification, mold inspection, and final casting inspection using CMM and X-ray to ensure dimensional accuracy and internal quality.

Lost Plastic Casting: Lost Plastic Casting, also known as Lost Foam Casting, involves creating a foam pattern that is coated with a refractory material. This pattern is then placed in a sand mold. When molten metal is poured into the mold, the foam pattern vaporizes, leaving behind a cavity that the metal fills. This process allows for the creation of complex and precise shapes with smooth surfaces and fine details. It is particularly useful for producing intricate parts with minimal machining required. The main advantage is the ability to produce near-net shape castings with high dimensional accuracy and surface finish.

Sand Casting: Sand Casting, on the other hand, involves creating a mold from a mixture of sand and a binding agent. A pattern, typically made of wood, metal, or plastic, is used to form the cavity in the sand mold. Once the mold is prepared, molten metal is poured into the cavity and allowed to solidify. After cooling, the sand mold is broken away to reveal the cast part. Sand Casting is versatile and cost-effective, suitable for producing large and heavy parts. It is widely used in various industries for casting metals like iron, steel, aluminum, and bronze.

In summary, Lost Plastic Casting is ideal for high-precision, complex parts, while Sand Casting is more versatile and cost-effective for larger, simpler components.

Lost foam casting is a modern metal casting method that uses a foam pattern, which is melted and replaced by molten metal inside a sand mold. This process enables the creation of highly accurate and complex metal parts.

Create a Foam Pattern

A pattern of the final part is made from expanded polystyrene (EPS) foam. This foam can be shaped by cutting or molding.

Assemble the Pattern

If the part is large or has complex features, multiple foam sections are glued together to form a full pattern.

Coat the Pattern

The foam pattern is coated with a ceramic slurry. This coating creates a barrier that helps produce a smoother surface finish and prevents sand infiltration.

Embed in Sand

The coated foam pattern is placed in a container and surrounded by unbonded dry sand. The sand is compacted, usually by vibration, to support the pattern and mold structure.

Pour Molten Metal

Molten metal is poured directly into the mold, vaporizing the foam pattern. As the foam burns away, the metal takes its place, solidifying into the final part.

Remove the Casting

After cooling, the sand is removed, revealing the finished metal casting. The part is then cleaned and finished as needed.

Lost foam casting, a process where molten metal vaporizes a foam pattern to form intricate parts, is widely applied in industries for its precision and efficiency. It produces complex automotive components like cylinder heads with intricate cooling passages, lightweight aerospace turbine blades with fine internal geometries, robust pump housings for industrial machinery with smooth fluid channels, durable wind turbine hubs and oil fittings for the energy sector, detailed custom sculptures for art, sturdy tractor gearbox housings for agriculture, and corrosion-resistant marine propellers with complex shapes, all with minimal machining and material waste.

Pattern Material:

Expanded Polystyrene (EPS): The most common foam for patterns, offering low cost, ease of shaping, and clean vaporization during casting.

Polymethyl Methacrylate (PMMA): Used for high-precision applications due to its cleaner burning properties, though more expensive than EPS.

Mold Material:

Silica Sand: The primary molding material, often mixed with binders like clay or resin, valued for its availability, heat resistance, and recyclability.

Binders: Clay, sodium silicate, or chemical resins to hold the sand together, ensuring mold stability during metal pouring.

Metals Used:

Aluminum: Widely used for its lightweight, corrosion resistance, and excellent castability, ideal for automotive parts like engine blocks and aerospace components.

Iron (Gray and Ductile): Common for heavy-duty parts like industrial machinery components and pump housings due to its strength and durability.

Steel (Carbon and Alloy): Used for high-strength applications, such as marine propellers and agricultural equipment, offering toughness and wear resistance.

Brass and Bronze: Employed for decorative castings and corrosion-resistant parts, like artistic sculptures and marine fittings.

Magnesium: Used in aerospace and automotive applications for its ultra-lightweight properties, though it requires careful handling due to reactivity.

Zinc: Occasionally used for small, detailed parts where lower melting points and good surface finish are needed.