Automated sand casting lines, including DISA MATCH 130 and Hunter HMP-20.

Metals (iron, aluminum, bronze).

Max casting size: 1000mm x 1000mm x 500mm. Tolerances: ±0.5mm.

Sand casting is a versatile and widely used metal casting process where molten metal is poured into a mold made of sand to create a solid metal part. The mold is formed by compacting sand around a pattern, which is a replica of the desired part. Once the metal cools and solidifies, the sand mold is broken away, leaving the finished casting.

Quality Management System: ISO 9001:2015 certified, ensuring consistent casting quality.

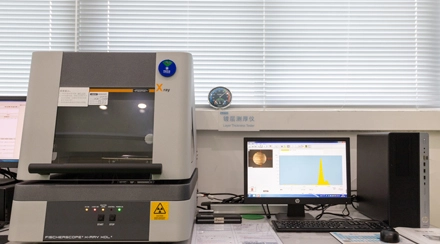

Inspection Equipment: Spectrometers, CMM, and hardness testers.

Quality Assurance Process: Material verification, mold inspection, and final casting inspection using spectrometers and CMM to ensure material composition and dimensional accuracy.

Pattern Creation:

A pattern, typically made of wood, metal, or plastic, is created to form the shape of the final part.

Mold Making:

The pattern is placed in a sand-filled mold box, and sand is packed around it to create the mold cavity.

Core Making:

Cores are used to create internal cavities or complex geometries within the cast part.

Melting and Pouring:

Metal is melted in a furnace and then poured into the mold cavity.

Cooling and Solidification:

The molten metal cools and solidifies within the mold.

Shakeout and Cleaning:

The sand mold is broken away, and the cast part is cleaned and finished.

Pattern: A replica of the desired part, typically made of wood, metal, or plastic. It shapes the mold cavity and includes allowances for shrinkage and machining.

Mold: The sand-based structure that forms the cavity where molten metal is poured. It consists of:

Cope: The top half of the mold.

Drag: The bottom half of the mold.

Sand Mixture: A blend of sand, clay, water, or other binders, packed around the pattern to create the mold.

Core: A sand-based insert placed in the mold to create internal cavities or complex features in the casting.

Gating System: Channels that guide molten metal into the mold cavity, including:

Runners: Pathways for metal flow.

Gates: Entry points where metal enters the cavity.

Sprue: The vertical channel through which metal is poured.

Risers: Reservoirs of molten metal that feed the casting as it cools, compensating for shrinkage.

Mold Box (Flask): A frame, typically metal, that holds the sand mold, split into cope and drag sections.

Molten Metal: The material (e.g., iron, steel, aluminum, or bronze) melted and poured into the mold to form the final part.

Finishing Tools: Equipment used post-casting for cleaning, removing excess material (runners/gates), and refining the part through grinding, machining, or heat treatment.

| Aspect | Die Casting | Sand Casting |

|---|---|---|

| Process | Molten metal is injected under high pressure into a reusable metal mold (die). | Molten metal is poured into a sand mold formed around a pattern. |

| Mold Material | Metal molds, typically steel or aluminum, designed for repeated use. | Sand mixed with binders, forming a single-use mold. |

| Production Speed | Fast, ideal for high-volume production due to quick cycle times. | Slower, better suited for low to medium volumes due to mold preparation time. |

| Surface Finish | Smooth, precise finish with minimal post-processing needed. | Rougher finish, often requiring additional machining or finishing. |

| Dimensional Accuracy | High precision with tight tolerances, suitable for complex, detailed parts. | Lower precision, with larger tolerances due to sand mold variability. |

| Cost | Higher initial costs for metal molds but lower per-unit cost in large runs. | Lower initial costs (sand is inexpensive), ideal for small batches or large parts. |

| Part Complexity | Excels at producing intricate, thin-walled parts with consistent quality. | Handles complex shapes but less suited for very thin or intricate features. |

| Material Range | Primarily used for non-ferrous metals like aluminum, zinc, and magnesium. | Versatile, works with both ferrous and non-ferrous metals (e.g., iron, steel, bronze). |

| Mold Reusability | Reusable metal dies, lasting thousands of cycles. | Sand molds are typically single-use, though sand can often be recycled. |

| Applications | Small, precise parts like automotive components, electronics, or appliances. | Large or custom parts like engine blocks, pump housings, or artistic castings. |

1. Cost-Effectiveness: Sand casting requires relatively low-cost materials (sand, clay, or binders) and reusable patterns, making it economical for both small and large production runs.

2. Versatility: It can cast a wide range of metals, including iron, steel, aluminum, and bronze, and accommodates complex shapes and sizes, from small components to large industrial parts.

3. Flexibility in Design: Sand casting allows for intricate geometries and internal cavities using cores, with patterns easily modified for design changes.

4. Scalability: Suitable for low-volume, custom parts or high-volume production, offering flexibility for different manufacturing needs.

5. Recyclability: Sand used in molds can often be reused, reducing waste and material costs.

6. Wide Material Compatibility: The process supports various alloys, enabling tailored material properties for specific applications.