In the world of manufacturing, where durability and precision are paramount, rubber calendering stands out as a cornerstone process for producing high-quality rubber goods. From automotive tires to medical seals, this technique ensures rubber products meet the rigorous demands of diverse industries. At BulkTEK, we’ve mastered rubber calendering to deliver components that combine strength, flexibility, and reliability. This article explores why rubber calendering is essential for creating durable rubber goods, its key processes, applications, and how it benefits industries like yours.

Rubber calendering is a manufacturing process that transforms raw rubber compounds into thin, uniform sheets or coatings through a series of rollers. These rollers, or calenders, apply controlled pressure and heat to shape the rubber, ensuring consistent thickness and surface quality. The process is highly versatile, allowing manufacturers to create rubber sheets, films, or coated fabrics tailored to specific applications.

At BulkTEK, our rubber calendering capabilities enable us to produce materials with precise tolerances, making them ideal for industries like automotive, medical, and engineering machinery. Whether it’s a conveyor belt or a gasket, calendered rubber delivers unmatched performance.

Durability in rubber goods comes from their ability to withstand wear, stress, and environmental factors. Rubber calendering plays a critical role in achieving this by:

Uniform Thickness: Calendering ensures consistent sheet thickness, which is vital for structural integrity in products like tires or seals.

Enhanced Strength: The process aligns rubber molecules, improving tensile strength and resistance to tearing.

Surface Quality: Smooth, defect-free surfaces reduce friction and wear, extending product lifespan.

Customization: Calendering allows for tailored formulations, such as adding reinforcements or coatings, to meet specific durability needs.

For example, in the automotive industry, calendered rubber is used in tire inner liners to ensure air retention and durability under high-speed conditions. BulkTEK’s expertise ensures these components perform reliably, even in demanding environments.

Rubber calendering involves several techniques, each suited to specific product requirements. Here’s a breakdown of the main processes:

Sheeting produces flat rubber sheets of uniform thickness, used in applications like gaskets or flooring. BulkTEK’s advanced calenders achieve thicknesses as low as 0.1 mm, perfect for precision applications.

In this process, rubber is applied as a thin layer onto fabrics or other substrates, creating products like conveyor belts or waterproof membranes. The coating enhances durability by combining rubber’s flexibility with the substrate’s strength.

Frictioning forces rubber into the weave of fabrics, improving adhesion for products like industrial belts. This technique is critical for applications requiring high tensile strength.

Profiling creates rubber sheets with specific textures or patterns, such as treads for tires. This enhances grip and durability in specialized applications.

Here’s a comparison of these processes:

Process | Application | Key Benefit | Industry Example |

|---|---|---|---|

Sheeting | Gaskets, flooring | Uniform thickness | Medical seals |

Coating | Conveyor belts, membranes | Enhanced durability | Food processing conveyors |

Frictioning | Industrial belts | Strong adhesion | Farm machinery belts |

Profiling | Tire treads, textured surfaces | Improved grip and wear resistance | Automotive tires |

Rubber calendering serves a wide range of industries, each with unique demands for durability and performance:

Automotive: Calendered rubber is critical for tire inner liners, belts, and hoses, ensuring durability under high stress and temperature. BulkTEK’s processes meet strict automotive standards.

Medical Equipment: Seals and diaphragms in medical devices require biocompatible, durable rubber. Our calendering ensures smooth surfaces for hygiene and reliability.

Engineering Machinery: Conveyor belts and gaskets in heavy machinery rely on calendered rubber for abrasion resistance and longevity.

Food Processing: Calendered rubber coatings on conveyor belts provide durability and compliance with FDA standards for hygiene.

Farm Machinery: Durable belts and seals, produced via frictioning, keep agricultural equipment running in harsh conditions.

At BulkTEK, we customize our calendering processes to meet the specific needs of these industries, delivering products that perform consistently.

Partnering with a trusted manufacturer like BulkTEK for rubber calendering offers several advantages:

Precision: Our state-of-the-art calenders achieve tolerances as tight as ±0.05 mm, ensuring consistent quality.

Material Expertise: We work with natural rubber, silicone, and synthetic compounds to match your application’s needs.

Scalability: From small prototypes to high-volume production, our processes are efficient and cost-effective.

Quality Assurance: Rigorous inspections, including thickness gauges and tensile testing, ensure every product meets specifications.

For instance, a recent project for a food processing client involved producing calendered rubber conveyor belts with a smooth, FDA-compliant coating. Using our coating process, we delivered 5,000 meters of material that exceeded durability expectations, helping the client reduce maintenance costs.

While rubber calendering is highly effective, it comes with challenges that require expertise to overcome:

Material Variations: Inconsistent rubber compounds can affect sheet quality. Solution: BulkTEK uses precise compounding and testing to ensure uniformity.

Roller Wear: Continuous use can degrade rollers, impacting precision. Solution: We implement regular maintenance and use high-grade steel rollers.

Thickness Control: Variations in thickness can compromise durability. Solution: Our automated control systems monitor and adjust roller gaps in real-time.

By addressing these challenges, BulkTEK delivers reliable, high-quality rubber goods for any application.

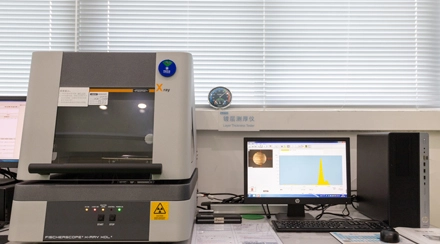

Modern rubber calendering relies on advanced technology to achieve superior results. At BulkTEK, we leverage:

Automated Calenders: Computer-controlled rollers ensure precise thickness and surface quality.

Real-Time Monitoring: Sensors detect variations in material properties, allowing immediate adjustments.

Quality Control Systems: Non-destructive testing verifies product integrity, ensuring durability.

These technologies enable us to serve clients across industries, from industrial distributors to global manufacturers, with consistent results.

At BulkTEK, we pride ourselves on delivering rubber calendering solutions that drive performance and durability. Our experienced team, cutting-edge equipment, and commitment to quality make us a trusted partner for industries worldwide. Whether you’re sourcing components for automotive, medical, or food processing applications, we offer:

Custom Solutions: Tailored rubber formulations and processes to meet your specifications.

Global Support: Reliable logistics to deliver products anywhere, on time.

Sustainability: Eco-friendly practices that reduce waste and energy consumption.

Ready to create durable, high-performance rubber goods? BulkTEK’s expertise in rubber calendering ensures your components meet the highest standards of quality and reliability. Whether you’re an industrial parts distributor or an end-user in automotive, medical, or engineering, we’re here to help. Explore our processing technology capabilities or contact us to discuss your project. Let’s build rubber products that last!